- Daikin named as Platinum sponsor of 2019 Future:Air seminar roadshow

- Gold sponsorships taken up by Mitsubishi Electric, A-Gas, Trane (distributed by Veolia) and ARC

- ARBS and Refrigerants Australia join industry associations AREMA and AMCA in support for Future:Air

- Expert international and Australasian speakers confirmed: AHRI President-CEO Steve Yurek, EPEE Director General Andrea Voigt and Ingersoll Rand business leader for Australia & New Zealand Stuart Kirkwood

- Seminars aimed at businesses and people that own, manage or service chillers and large air conditioning equipment – industry must act now to prepare for coming changes

With less than three weeks to go until the first Future:Air breakfast seminar takes place, this educational roadshow for businesses and people that own, manage or service chillers and large air conditioning equipment has attracted massive industry support, with Daikin confirmed as Platinum Sponsor with naming rights.

Daikin is joined by Gold Sponsors Mitsubishi Electric, A-Gas, Trane (distributed by Veolia) and the Australian Refrigeration Council while Refrigerants Australia has secured a silver sponsorship.

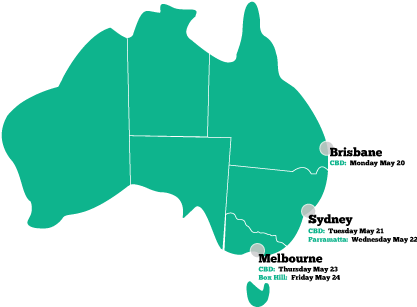

Industry trade-show ARBS has also thrown its support behind Future:Air, an industry-run, not-for-profit partnership between industry associations AREMA and AMCAthat will run the five breakfast seminars across Brisbane, Sydney and Melbourne from May 20-24 this year.

Future:Air, in association with Daikin, will deliver vital cutting-edge information to help prepare businesses that own, manage or repair chillers and large air conditioning equipment for the arrival of new systems, equipment, technology and regulations.

Taking place in Brisbane, Sydney, Parramatta (NSW), Melbourne and Box Hill (VIC) from May 20-24, 2019, each event will take place between 7.30am and 9.30am with full plated breakfast provided.

Subsidised by contributions from industry associations and corporate sponsorship, tickets are priced at just $99 per delegate and available from FutureAir.acthrough a secure online booking system. Corporate tables of eight are also available at a discount and can be booked by emailing support@futureair.ac.

The seminars will be presented by the following expert speakers from major international and Australasian industry associations and companies:

- Stephen R Yurek (United States)

CEO and President of AHRI, joined AHRI in 2002 as Vice President of Policy and Public Affairs and General Counsel

- Andrea Voigt (Europe)

Director General of EPEE, guiding members towards strong common positions and representing them in front of European institutions, governments and business leaders

- Stuart Kirkwood (Australasia)

Business Leader for Australia & New Zealand Region, Ingersoll Rand, with 35 years’ HVAC industry experience including nine in Asia. Responsible for Trane and Thermo King brands, he also represents AREMA on several Australian Standards Committees

- Greg Picker (Australia)

ExecutiveDirector of the Air conditioning and Refrigeration Equipment Manufacturers Association of Australia (AREMA) and Refrigerants Australia since 2013 and has over 20 years’ experience dealing with climate change and energy policy, including with the UN Framework on Climate Change, the Australian Government and AECOM

Stephen R. Yurek has been Chief Executive Officer and President at The Air-Conditioning, Heating and Refrigeration Institute (AHRI) since January 1, 2010 and 2007 respectively.

Stephen R. Yurek has been Chief Executive Officer and President at The Air-Conditioning, Heating and Refrigeration Institute (AHRI) since January 1, 2010 and 2007 respectively. Andrea Voigt

Andrea Voigt